Chini Ka Cup Factory: Top Coolcap Manufacturers & Suppliers in the Industry

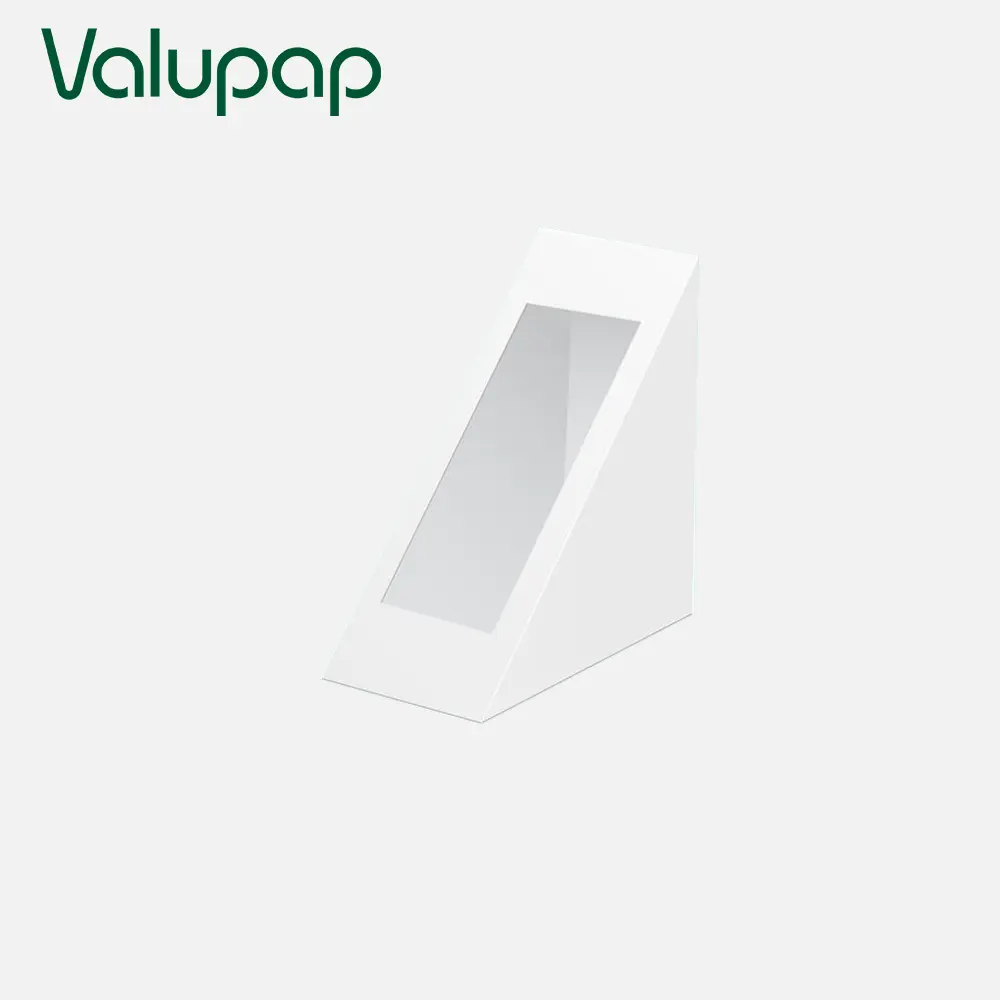

High-quality Chini Ka Cup Factory products are within reach! With extensive experience as both an ODM and a manufacturer, we offer an impressive selection of beautifully crafted sugar cups ideal for various business needs. As a trusted exporter, our commitment to meeting international standards is unwavering, all while keeping affordability in mind. At NINGBO VALUPAPER CO., LIMITED., our dedicated team prioritizes quality and reliability. We collaborate closely with B2B purchasers to deliver customized solutions that enhance your brand. From eco-friendly options to elegant designs, we provide innovative products and exceptional service tailored to you. Partner with us to elevate your product line with our exquisite Chini Ka Cups and ensure your business stands out. We are here to support your growth and success!

Best Methods To Chini Ka Cup Factory Your End-to-End Solution Your Trusted OEM Partner

Best Methods To Chini Ka Cup Factory Your End-to-End Solution Your Trusted OEM Partner

| Method | Description | Advantages | Suitable For |

|---|---|---|---|

| Injection Molding | A manufacturing process for producing parts by injecting material into a mold. | High precision, scalability, and material efficiency. | Large scale production runs. |

| Blow Molding | Used to produce hollow plastic parts by inflating heated plastic inside a mold. | Ideal for creating lightweight, durable containers. | Bottles and hollow containers. |

| Thermoforming | A process that uses heat to make plastic sheets pliable for shaping and forming. | Quick setup time and low material waste. | Short to medium run production. |

| Rotational Molding | A method for producing plastic products by rotating a mold filled with plastic powder. | Excellent for large, complex shapes and consistent wall thickness. | Large containers and parts. |

| 3D Printing | Additive manufacturing technology to create parts layer by layer. | Flexibility in design and rapid prototyping. | Custom parts and prototypes. |