Definition and Difference between PLA and PE

Choosing between PLA and PE coatings depends on specific requirements and applications. Industries such as packaging, automotive, and healthcare increasingly adopt these coatings for their unique properties. Understanding the difference between PLA and PE is crucial, especially when considering what is the difference between PLA and PE coating. This knowledge can help professionals make informed decisions that align with their sustainability and performance goals.

Key Takeaways

- Pla Coatings are biodegradable and derived from renewable resources, making them a sustainable choice for eco-conscious businesses.

- PE coatings offer superior moisture and grease resistance, making them ideal for Food Packaging applications that require durability.

- Consider the specific needs of your application, such as environmental impact and performance, to make an informed decision between PLA and PE coatings.

Definitions of PLA and PE

Polylactic acid (PLA) and polyethylene (PE) are two prominent types of coatings used in various industries. Understanding their definitions helps clarify their applications and benefits.

PLA is a thermoplastic polyester with the backbone formula (C3H4O2)n. It derives from lactic acid, which can be produced biologically or chemically using bacteria. The manufacturing process involves several steps:

- Fermentation of starch produces ammonium lactate.

- Processing of ammonium lactate separates ammonia, yielding lactic acid.

- Oligomerization of lactic acid forms a prepolymer.

- Depolymerization creates lactide, which polymerizes using catalysts like stannous octoate.

This process allows PLA to be biodegradable or long-lasting, depending on the additives used.

In contrast, PE is a widely used plastic with the chemical formula (C2H4)n. It consists of long chains of carbon and hydrogen atoms. The manufacturing processes for PE include:

| Aspect | Details |

|---|---|

| Chemical Composition | Polyethylene (PE) has the chemical formula (C2H4)n, consisting of long chains of carbon and hydrogen atoms. |

| Manufacturing Processes | 1. Polymerization of Ethylene 2. Thermal Cracking of High-Density Polyethylene (HDPE) 3. High-Pressure Polymerization 4. Modification of Polyethylene Each method yields different properties suitable for various applications. |

Both PLA and PE coatings offer unique characteristics that cater to specific needs in industries such as packaging, automotive, and healthcare. Understanding these definitions lays the groundwork for evaluating their environmental impact, performance, cost, and applications in the following sections.

Difference Between PLA and PE Environmental Impact

The environmental impact of coatings plays a crucial role in selecting between PLA and PE. Each coating presents distinct advantages and challenges that affect sustainability.

-

Greenhouse Gas Emissions:

- Lifecycle greenhouse gas emissions for PLA coatings are generally lower than those for PE coatings. This difference is particularly notable when considering end-of-life scenarios and biodegradability.

- PLA containers can be 100% recyclable and/or compostable, resulting in approximately 28 kg of CO2 emissions compared to 830 kg of CO2 for PET.

- Studies indicate that using bio-plastics like PLA instead of fossil-based plastics can lead to significant energy and greenhouse gas emissions savings. The production of PLA bottles has shown to reduce CO2 emissions, lower toxicity, and decrease the demand for non-renewable energy compared to PET.

-

Biodegradability:

- PLA coatings exhibit impressive biodegradability rates under industrial composting conditions. Research shows that PLA can degrade to 81% ± 10% in just 58 days. Other studies report 86% degradation of PLA plates after 120 days and 75% degradation after 90 days with 2 mm pieces of PLA.

- In contrast, PE coatings do not biodegrade effectively. They can persist in the environment for hundreds of years, contributing to long-term pollution.

-

Microplastic Pollution:

- Recent studies highlight the potential health risks associated with PLA microplastics. These microplastics can lead to gut dysbiosis and inflammation. The degradation of PLA into smaller nanoparticles raises concerns about its impact on metabolic processes in organisms. Incomplete degradation of PLA microplastics has been linked to neurotoxicity and acute inflammation, especially as PLA is increasingly used in food packaging.

-

Water and Energy Consumption:

- The production of PLA requires significantly less energy compared to traditional plastic-coated paper, including PE. Specifically, PLA production consumes 65% less energy and generates 63% fewer greenhouse gases than its traditional counterparts.

Difference Between PLA and PE Performance

When evaluating the performance of PLA and PE coatings, several factors come into play, including mechanical strength, barrier properties, and resistance to environmental conditions. Understanding these differences helps industries select the right coating for their specific applications.

-

Mechanical Strength:

- PLA coatings exhibit a tensile strength ranging from 50 to 70 MPa, with a Young’s modulus of 3 GPa and an elongation at break of 4%.

- In contrast, PE coatings provide superior durability, making them more suitable for high-pressure applications. While both coatings share similar mechanical properties, PE offers better resistance to liquids and corrosion.

-

Barrier Properties:

- PLA coatings enhance humidity resistance but fall short in gas permeability compared to PE coatings.

- Research indicates that PLA has poor gas barrier properties, which can limit its effectiveness in certain packaging applications. Ongoing studies aim to improve PLA's barrier properties through the incorporation of composites and fillers, indicating potential advancements in its application for packaging.

-

Performance Under Environmental Conditions:

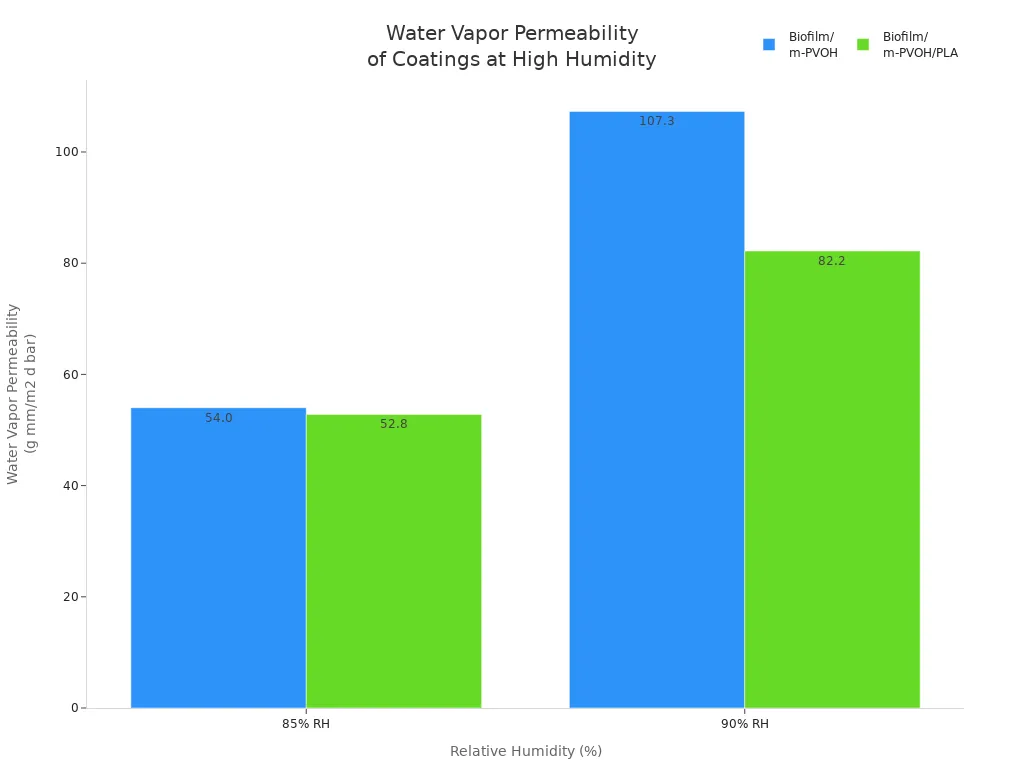

- The performance of coatings under high temperature and humidity is crucial for many applications. A comparison of water vapor permeability reveals significant differences:

Coating Type Water Vapor Permeability (g mm/m² d bar) Relative Humidity (%) Biofilm/m-PVOH 54.0 85% Biofilm/m-PVOH/PLA 52.8 85% Biofilm/m-PVOH 107.3 90% Biofilm/m-PVOH/PLA 82.2 90%

-

Chemical Resistance:

- PE coatings outperform PLA in terms of chemical resistance. For instance, Pe Coated boards exhibit a water vapor transmission rate (WVTR) of 10.4 g/m².day, while PLA coated boards have a significantly higher WVTR of 64.9 g/m².day. This difference indicates that PLA is less suitable for packaging moist or wet foods, as it degrades into harmless products when in contact with water.

-

Shelf Life Implications:

- The durability and moisture resistance of coatings directly affect the shelf life of products. A comparison of PLA and PE coatings reveals the following:

Coating Type Durability Moisture Resistance Biodegradability Environmental Impact PE High Excellent Non-biodegradable Complicates recycling PLA Moderate Limited Biodegradable Eco-friendly option

Difference Between PLA and PE Cost

Cost considerations play a vital role in the decision-making process for manufacturers choosing between PLA and PE coatings. The initial investment for PLA coatings tends to be higher due to several factors. Manufacturers face increased material prices, the need for specialized machinery, and employee training. Additionally, adjustments in the supply chain can add to the overall costs. However, switching to PLA can yield long-term benefits. These include reduced packaging costs from using renewable resources, eligibility for environmental incentives, and an enhanced brand image that attracts eco-conscious consumers.

The fluctuations in raw material costs for both PLA and PE coatings significantly impact pricing. Tariffs and supply chain dynamics often lead to increased prices. For example, dual tariffs on coating materials and packaging metals have prompted manufacturers to explore nearshoring and vendor diversification to mitigate these impacts. Furthermore, geopolitical issues, such as trade disputes, can disrupt supply chains, causing significant price fluctuations for raw materials.

The cost of crude oil also plays a critical role in determining the prices of plastic raw materials, including polyethylene. As crude oil prices fluctuate, they directly affect the feedstock costs for producing plastics. This sensitivity to demand fluctuations can lead to significant price changes in the coatings market. As demand rises across various sectors, manufacturers often face pressure to pay more to secure necessary materials, resulting in price hikes.

Difference Between PLA and PE Applications

PLA and PE coatings serve distinct purposes across various industries, particularly in food packaging and medical applications. Understanding these differences helps manufacturers select the appropriate coating for their needs.

In the food packaging industry, PLA finds extensive use due to its biodegradable properties. Common applications include:

- Fabricating films for wrapping food items.

- Making cups that provide a barrier against leaks.

- Creating containers for salads and other prepared foods.

- Coating paper cups and bowls to ensure food safety.

| Application Type | Description |

|---|---|

| Paper Cups | Used to produce cups that prevent leaks and spills. |

| Paper Bowls | Coated to ensure food safety and prevent leakage. |

| Lids | Help maintain the integrity of food packaging. |

| Boxes | Versatile for storing both hot and cold food items. |

| Coffeehouse Cups | Starbucks uses PLA coating in its cups to reduce environmental impact. |

Conversely, PE coatings excel in applications requiring moisture and grease resistance. They are commonly used in:

- Disposable coffee cups that hold hot beverages securely.

- Takeout boxes that protect food from moisture and grease.

- Fast food wrappers that prevent grease from seeping through.

- Bakery products packaging that maintains freshness.

PE coatings are highly valued for their ability to keep food fresh and safe from contaminants. Their strong barrier properties make them ideal for various food items, ensuring quality and safety.

In medical applications, PLA's biocompatibility makes it suitable for surgical sutures and wound management. It minimizes inflammation and foreign body reactions, enhancing patient comfort. PE, while less common in medical settings, still finds use in packaging medical devices due to its durability.

Understanding the difference between PLA and PE applications allows businesses to make informed choices that align with their operational goals and sustainability initiatives.

In summary, PLA and PE coatings differ significantly in several areas:

- Environmental Impact: PLA is biodegradable and derived from renewable resources, while PE is petroleum-based and non-biodegradable.

- Performance: PE offers superior durability and moisture resistance, making it ideal for food packaging.

- Cost: PLA generally incurs higher production costs, which may deter some manufacturers.

When choosing between these coatings, consider factors such as environmental impact, performance requirements, and consumer preferences. As sustainability becomes increasingly important, businesses must weigh immediate costs against long-term benefits.

Tip: Evaluate your specific application needs to make an informed decision that aligns with your sustainability goals.

FAQ

What are the main advantages of PLA coatings?

PLA coatings are biodegradable, derived from renewable resources, and have lower greenhouse gas emissions compared to traditional plastics.

How do PE coatings perform in wet conditions?

PE coatings excel in moisture resistance, making them ideal for packaging items that require protection from water and grease.

Can PLA coatings be recycled?

Yes, PLA coatings can be recycled or composted, depending on local facilities and regulations, promoting a more sustainable waste management approach.